Current Themes & Projects

Analysis of Steel-Concrete Composite Shell Structures

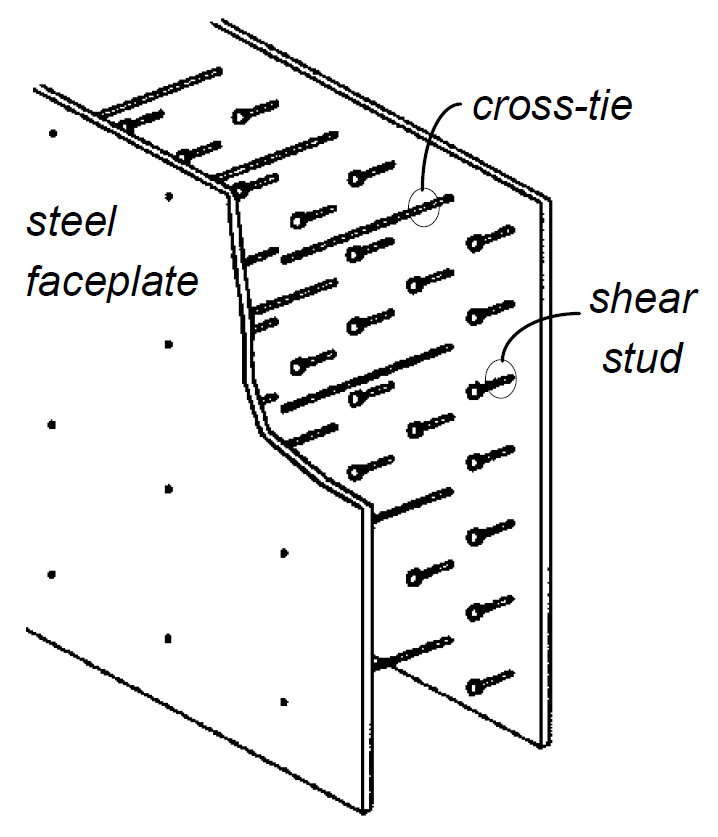

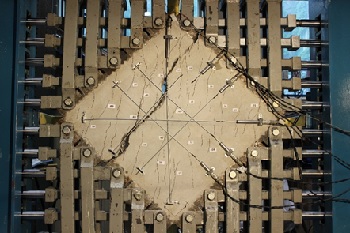

Steel-concrete (SC) composite elements consist of a thick concrete core section sandwiched between thin steel faceplates. The element core typically contains no conventional reinforcement, but utilizes shear studs and cross-tie bars to join the core to the faceplates, and to serve as transverse shear reinforcement. In the past, there had been considerable interest in the use of SC systems for the construction of nuclear power plant structures due to the significant cost savings which could be attained as a result of employing modular SC systems. Today, the increasing need for design of seismic and impact resistant structures has led to renewed interest in the development of SC composites. Further development of the software program VecTor4, a nonlinear finite element analysis program for reinforced concrete shell structures, focused on incorporating SC analysis capabilities is currently underway. The resulting analysis procedure will be used to perform a preliminary assessment regarding the behaviour of SC composite shell elements under seismic loading conditions, a research area not previously investigated. The capability of SC elements to achieve desirable ductility levels, specifically under three-dimensional shear critical loading conditions, will be investigated.

Steel-Concrete (SC) Composite Element

(adapted from Usami et al., 1995)

Analysis of Mixed-Type Structures

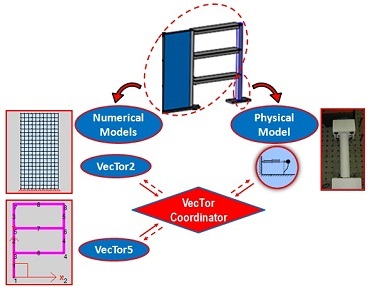

The current suite of VecTor analysis programs were developed such that each program is capable of modeling one particular type of structure only. However, there are many applications in which different types of structural components act together. A master program is being developed to account for the interactions between substructures and enable the analysis of mixed-type structures using the VecTor computational methodologies and material model formulations. The concept is to compute displacements at master points which are shared between two or more substructures; based on the computed displacement at each of these principal points, analyses would be performed for each substructure using appropriate VecTor program. This allows the use of parallel processing which results in faster and more efficient analysis.

In addition, work is being done to make the VecTor programs compatible with hybrid simulation tests. Hybrid simulation testing requires the use of a continuous feedback system between the physical model and the numerical model, often in real-time. Enabling the use of the VecTor programs as the numerical model will result in more accurate simulations of the complex nonlinear behaviour of concrete structural elements and, thus, more accurate hybrid simulations.

Mixed-Type Analysis

Development of Simplified Analytical Tools for Impact and Impulsive Loading Analysis of Reinforced, Prestressed and Steel-Composite Concrete Slabs

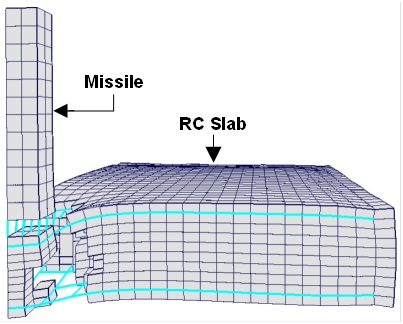

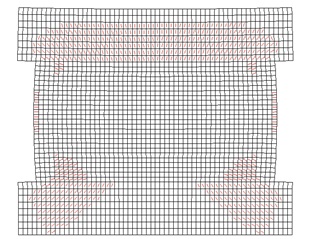

Current methods used for analysis of reinforced concrete (RC) structures under impact loading are mainly based on single degree of freedom (SDOF) methods or complex hydrocodes. Most SDOF methods tend to simplify the behavior of the structure, and cannot deliver results in required detail. While, hydrocodes overcome the problems caused by simplification of the behavior, they require a large number of material inputs and modelling of the structure in high detail. The goal of this research is to develop a simplified analytical tool to analyze reinforced concrete slabs under impulsive loading particularly soft and hard missile impacts. The VecTor programs, developed at the University of Toronto, are nonlinear finite element analysis programs for RC structures. These programs are capable of the analysis of shear critical structures accurately using less degrees of freedom than typically required by a hydrocode. This study focusses on improvement of VecTor programs to increase their capability and performance to handle missile impact analyses, where localized severe shear failure is observed.

Hard missile impact analysis in VecTor3

(Quarter of the slab is modeled due to symmetry)

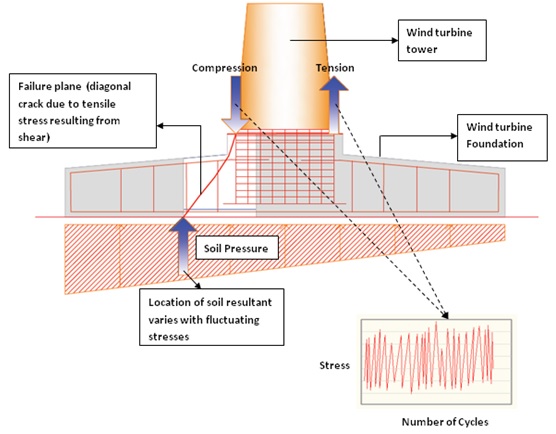

Improved Analysis and Design of Wind Turbine Foundations

The susceptibility of constituent materials of a wind turbine foundation (especially reinforcing steel) to fracture under cyclic loading is high, when induced dynamic stresses as a result of wind or waves in the foundation are not properly mitigated in design.

Over the years, the norm in wind turbine foundation design against fatigue considers the material provision to be adequate when the design life cycle is lower than the number of cycles leading to failure at a given stress level. This approach is acceptable for reinforced concrete elements in flexure, as long as bond fatigue does not govern. Hence, the S-N curves and damage models developed for concrete and steel reinforcing bars are sufficient in predicting fatigue failure of beams governed by flexure. However, the behaviour of stirrups under shear fatigue is by far more complex and requires a thorough approach. As such, available S-N curves and damage models may not give appropriate predictions if salient mechanisms in shear fatigue are not taken into consideration.

Generally, increased volume of materials are provided to reduce the materials stresses until the corresponding number of cycles to failure increases beyond the design service life cycles. However, some obvious flaws in increasing the amount of stirrups exist. These include: congestion of reinforcement, excess construction time, and poor foundation concreting. In addition, under shear fatigue, the influence of embedded stirrups on the diagonal crack initiation is insignificant. Previous research has shown that fatigue damage accumulation of stirrups begin after diagonal crack. Thereafter, fracture of the stirrups or longitudinal reinforcing bars at intersections with diagonal crack may occur and result in the collapse of the structure. Based on these, an appropriate means of extending the number of cycles at which these cracks occur is deemed crucial.

Research on steel fibre has shown its effectiveness in flexure and tension under monotonic loading, impact loading and fatigue resistance in flexure. As such, it is paramount that its influence on shear fatigue diagonal crack is investigated. Further, developments of models which adequately predict reinforced concrete elements responses under constant and variable fatigue load are invaluable. The extension of such models to include the influence of steel fibre is also vital.

Currently, the behaviour of steel fibre in enhancing shear fatigue resistance of beams is being investigated in order to improve the analysis and design of wind turbine foundations. Tests on plain and steel fibre reinforced concrete specimens are to be conducted under tensile and compressive fatigue loads in order to develop materials damage models. The models to be developed are also to be corroborated with the behaviour of two large scale wind turbine foundations to be tested under fatigue loading.

Behaviour of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) and Hybrid Steel Fibre Reinforced Concrete (HySFRC)

UHPFRC is a new generation material typically containing short steel microfibers with volume ratios of up to 5%. Its outstanding material characteristics include self-consolidating workability, high compressive strengths, high tensile strengths, a strain-hardening post-cracking response, and excellent crack control properties. The high tensile strengths makes it possible, in some cases, to significantly reduce or eliminate conventional reinforcement, reducing congestion and allowing for thinner and more economical sections. These attributes make it advantageous in high-performance applications such as offshore platforms and nuclear power plant buildings, bridge decks, and blast and impact resistant structures. HySFRC contains high strength steel micro- and macro- fibres in effective ratios so as its behavior to be superior compared to the use of a single type of fibre, with no other modifications in the matrix mix. This characteristic is attributed to the synergistic effect of the fibre cocktails.

For both materials the research is driven towards the behavior in shear under monotonic and cyclic loading. Our ability in effectively designing the structures above rides on the development of appropriate constitutive models for the characterization of the novel cracked composite. To more clearly isolate and study the shear behaviour, a series of panel specimens will be tested using the Panel Element Tester facility. The models to be developed will be implemented to facilitate use in the VecTor 2 Finite Element analysis program.

HybSFRC under monotonic shear loading after failure

Stochastic Nonlinear Finite Element Analysis of Reinforced Concrete Structures

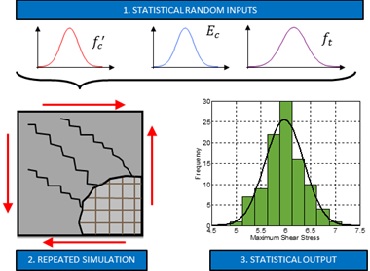

Increasing fiscal limitations to maintenance budgets in recent decades mean that Canadian infrastructure now faces an urgent need to reliably predict the safety of deteriorating structures. The analysis of a deteriorating structure can be a challenging task for a structural engineer. Deterioration effects may not be immediately apparent, they are difficult to accurately quantify, and the engineer is forced to make a large number of assumptions. When faced with such uncertainty, it is practical to employ stochastic analysis techniques to predict the probability of failure. As part of the IC-IMPACTS initiative, existing statistical distributions will be implemented into VecTor2 to randomize the program inputs and allow the user to conduct Monte Carlo simulations. Behaviour models for corroded reinforced concrete, the effect of corrosion-induced cracking, deterioration of bond strength, and variation in the area of steel will be researched and implemented into VecTor2 providing the ability to analyze corroded reinforced concrete. The ability to quantify the reliability of deteriorating infrastructure will provide engineers with the tools to assess the safety of such infrastructure and potentially predict and prevent events like the collapse of the reinforced concrete factory structure in Bangladesh in April 2013, or the Laval bridge collapse in September 2006. These tools will ultimate contribute to increased public safety in Canada and India.

Monte Carlo Simulation Using MCFT

Modelling of Alkali-Aggregate Reaction Effects in Reinforced Concrete Structures

Chemical deterioration of concrete in the form of alkali-aggregate reaction (AAR) is a slow-evolving but progressive process leading to expansion and cracking of concrete. An extensive amount of research has been made since it’s discovery in 1940 due to an increased manifestation of the reaction in major structures such as bridges, dams and nuclear power plants. However, it still represents an important durability issue that causes significant economic damage worldwide. Numerical simulation of AAR effects on concrete plays an important role in determining the behavior of AAR-affected structures. As such, constitutive models for AAR-affected concrete were implemented within the architecture of VecTor2. The AAR expansion was treated as a non-recoverable offset strain using a computational procedure previously developed for elastic and plastic offset strains. Two distinct mechanisms were taken into consideration to fully capture the effects of AAR on concrete: material expansion and the accompanying changes in mechanical properties. Verification studies are being performed at two levels: material-level (cylinders, prisms, and cubes) and structural-level (beams, shear walls) by modelling AAR-affected specimens reported in the literature. The analytically determined responses currently show good agreement with the experimental results. The current accuracy will be improved once conclusions are drawn from the material-level investigation and the structural testing, parts of the study that is currently underway.

Crack pattern for AAR-affected shear wall

Finite Element Modelling of Corrosion Damaged Reinforced Concrete Structures

Corrosion of steel is the predominant deterioration mechanism of reinforced concrete structures throughout the world. Corrosion can affect the strength and serviceability by reducing the cross-sectional area of reinforcing steel. The degree to which the structural performance is degraded depends on the nature and severity of corrosion and the location of its occurrence. Considering the great number of old and defective reinforced concrete structures that are present within our built environment, there is a considerable need for reliable tools to assess the effects of corrosion on the behaviour of reinforced concrete. One of the tools that can assist in drawing proper conclusions on the state of a corroded reinforced concrete structure is finite element modelling. In light of the current development of numerical models for corrosion damage, this study focuses on implementing corrosion damage constitutive models within the algorithms of VecTor2.

Unifrom and pitting corrosion implemented in VecTor2